Recreational Rigging--Moving a knee mill.

March, 2012.

[Click on pictures to enlarge them]

So

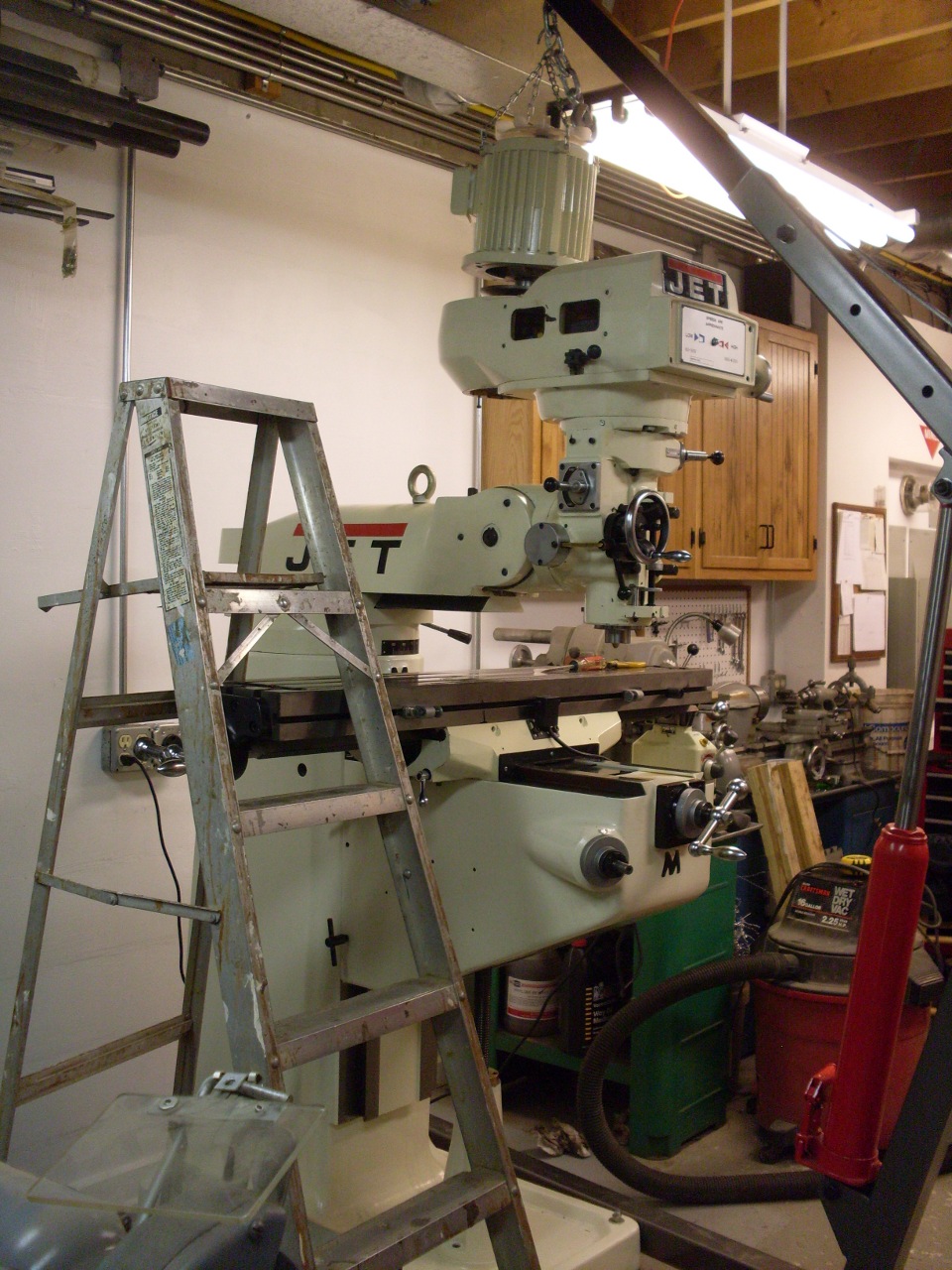

I was looking for a milling machine, and had just about decided on an

RF-45 type mill when I was perusing Craig's List and saw an ad for a

Jet JTM-4VS Bridgeport clone mill for not too much more than the RF-45.

I called about it, met a nice guy named Dave who used it for

gunsmithing, but wanted to sell it to go back to school and start a new

career. The mill was less than five years old, and looked pretty

well cared for.

Before I committed to buying the Jet, I wanted

to check out the cost of moving it. The 2420 pound machine had

to come up the stairs out of Dave's basement shop and across town to my

place. The cost to get it to my garage amounted to about a third

of the cost of the mill, which took me to the absolute limit of my

budget for the project. Unfortunately, my shop is also in my

basement, which is up three steps to a tiled entryway, across 12 feet

of oak strip floor, and down 16 steps to the basement, where the bottom

riser is only about 36 inches from a facing wall.

I

didn't want to pass on the machine, so I decided to have the machine

deposited in my garage, then I could take my time figuring out a way to

get it to the shop myself, breaking it down if necessary. If I

got into trouble, I could still call the riggers back to rescue me.

Here

it is in Dave's basement on moving day. Dave and I had already

removed the table and turned the head upside down to make it more

compact.

I

hired Wings Transfer in Omaha to do the move. They brought seven

guys but made the whole process look almost effortless. It was

obvious they knew what they were doing. They had the mill on

their truck in just a couple of hours.

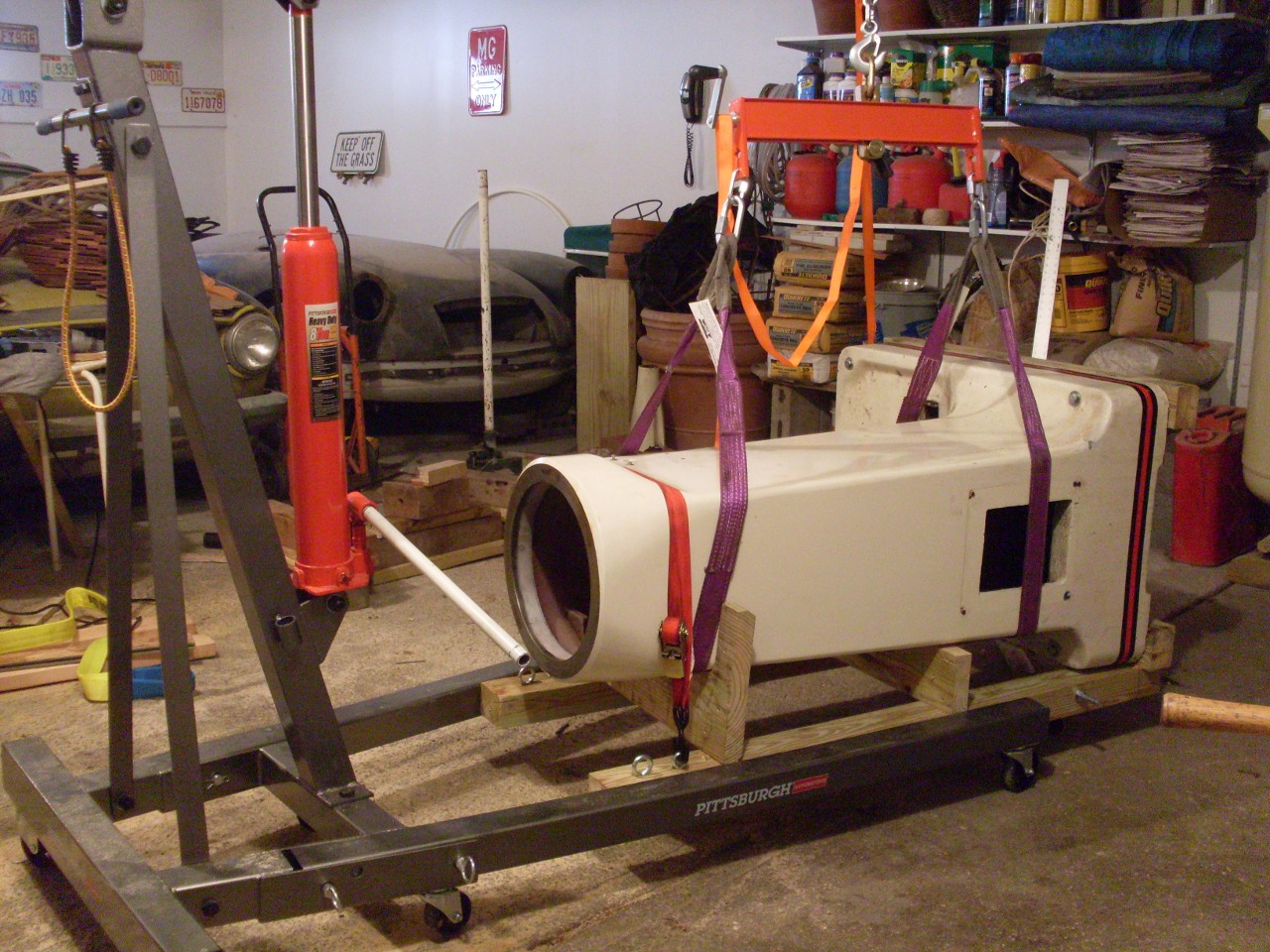

Less than an hour after that, it was sitting in my garage:

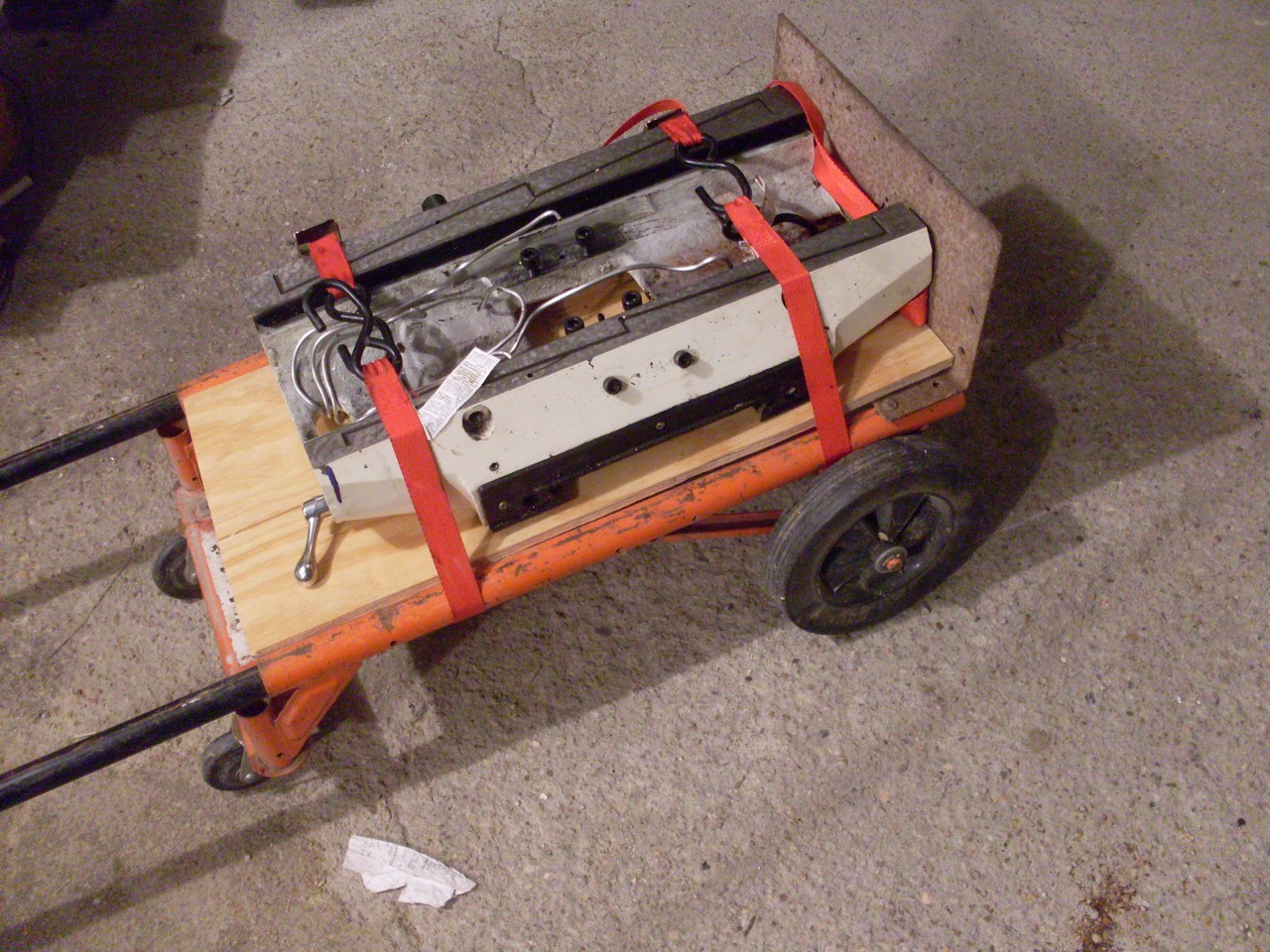

The

saddle and motor were light enough that I could get them off

without help. I could tell when I removed the motor that there

appeared to be a lot of grease on and around the drive belt and

pulleys. This didn't seem right. I surmised later that it

was because the head was upside down for a few days, and the grease

flowed.

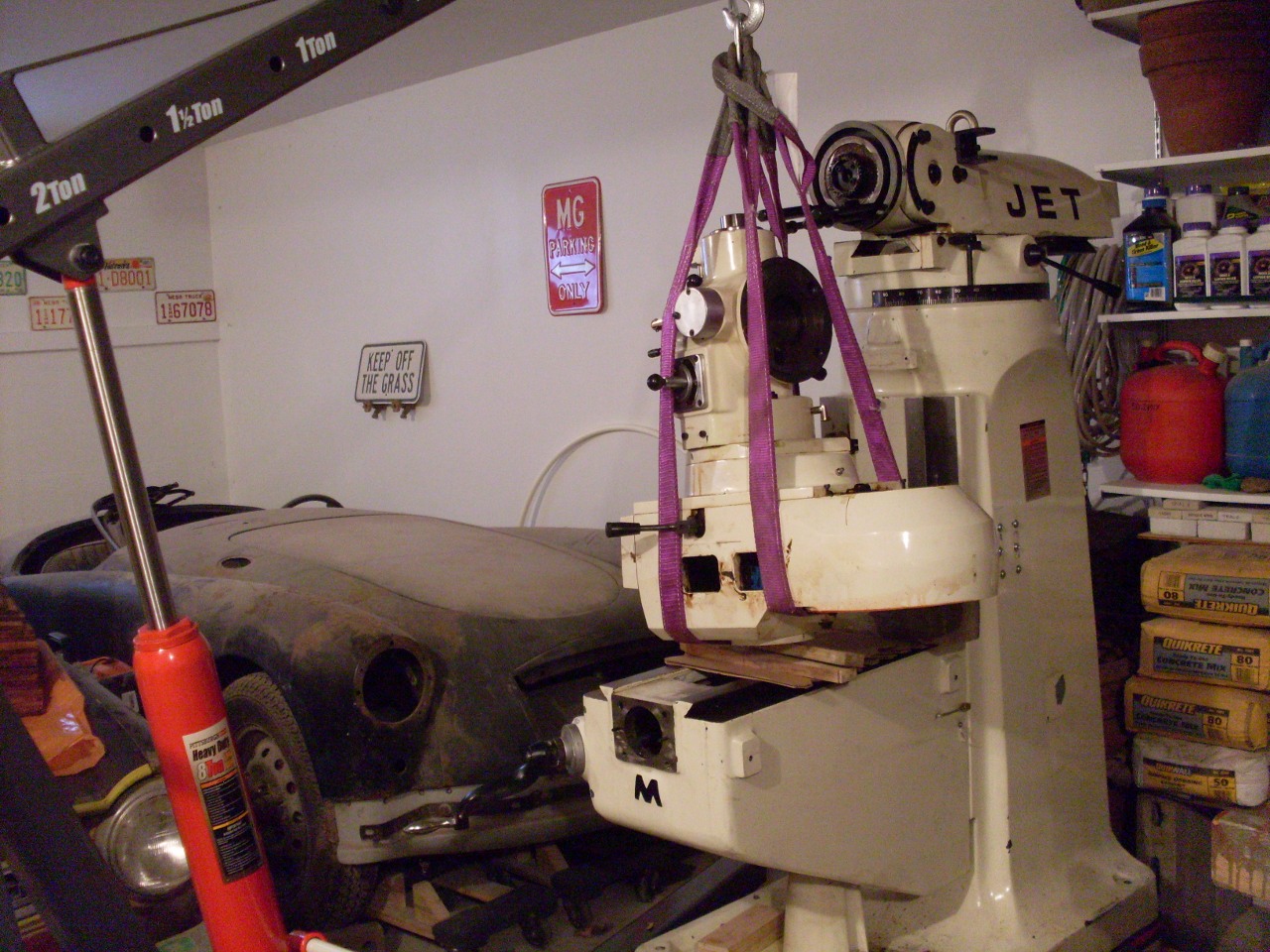

Next,

the head with the variable speed drive system came off. Since I

was doing this job solo, I needed a skyhook for this.

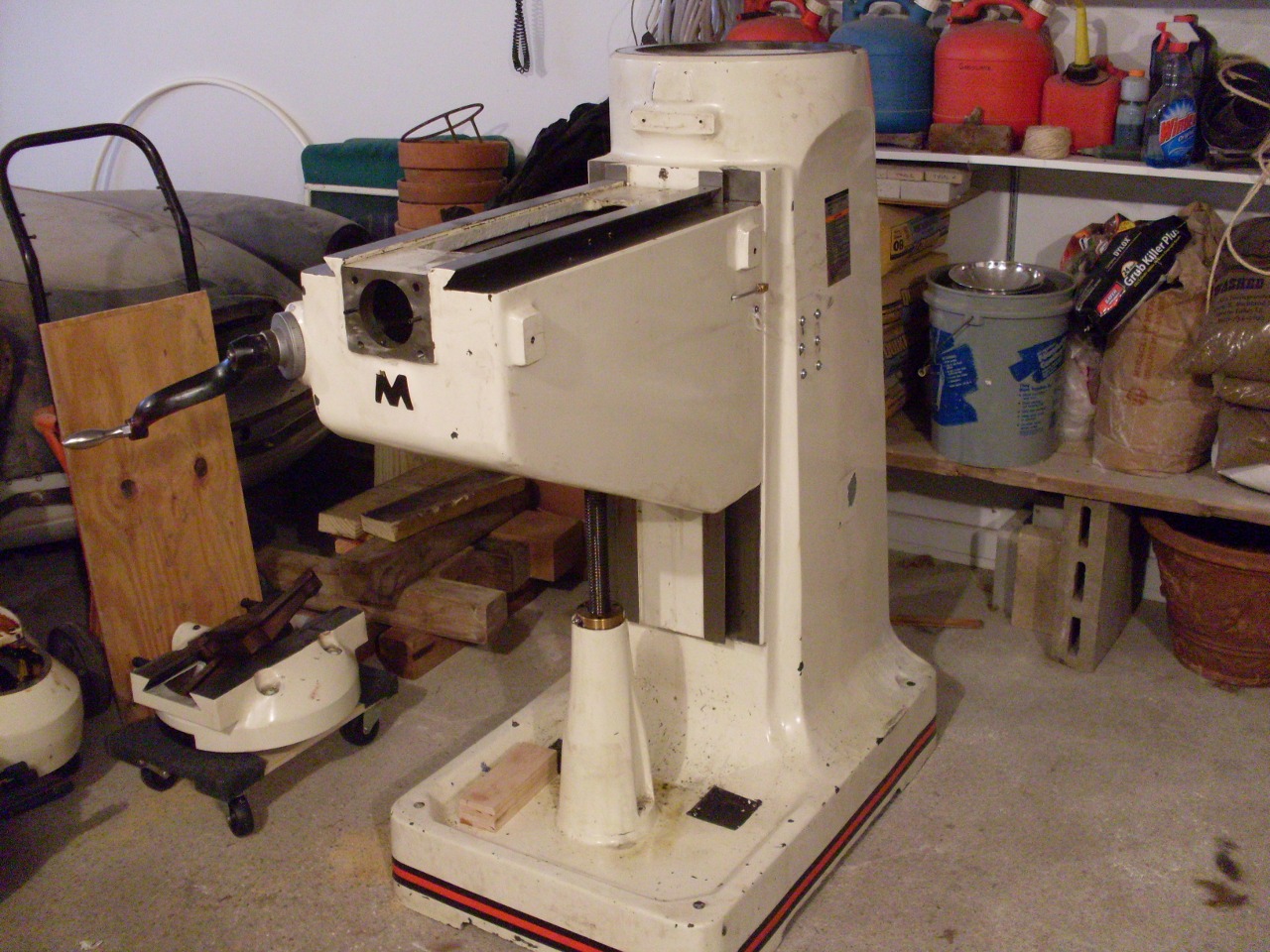

The ram and turret were next:

Then

the knee. It must weigh close to 300 pounds. It has to come

up high enough to clear the column dovetails. I had maybe an inch

to spare before the boom would have hit the ceiling.

To

get the bigger pieces down the stairs, I fashioned a pair of

wooden tracks screwed to the stairs, and a sled to run in the tracks.

I put the parts on the sled with the crane, and push the sled to the top of the stairs.

Then

I lag bolted a hand winch through the floor into the framing below.

I did this in a place where I removed a threshold, so the holes

would be covered. The

winch is a worm gear type rated for one ton. The worm gear design

is self-holding: there is no need for a ratchet or pawl mechanism to

hold the weight. The rug is on the cable to keep it from whipping in the unlikely case that it would snap.

At

the bottom of the stairs, I had a come-along hanging from the

ceiling framing to help get the piece from the sled to a dolly.

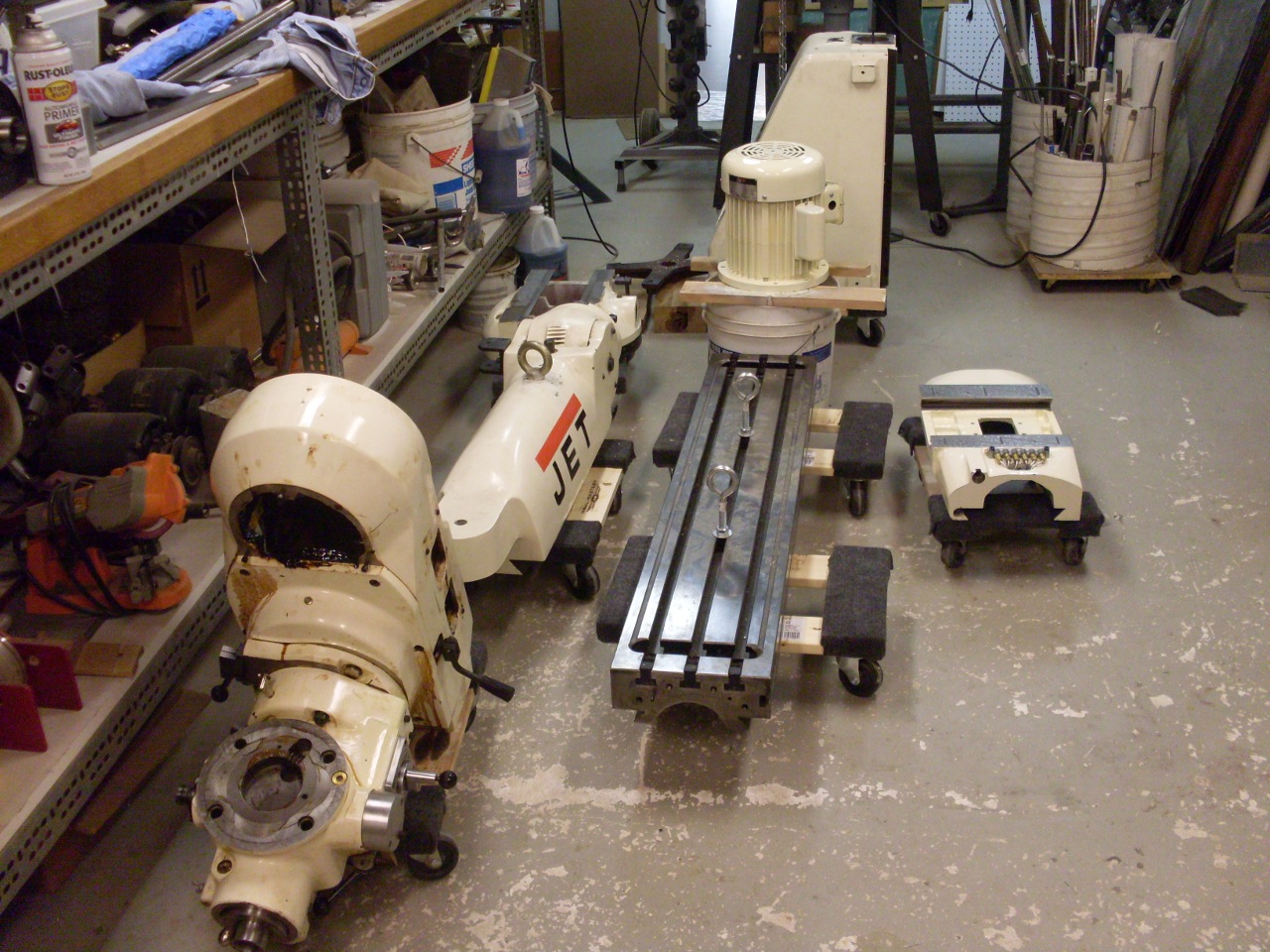

Here are all the parts in the shop except for the column:

This

bad boy weighs close to 800 pounds. I fashioned a custom sled to

it before I tipped it on its side. It had to go down the stairs

on its side because of the limited room at the bottom. The shape of the column base was the reason that the tracks on the stairs were offset to one side.

I

don't have pictures of the column coming down the stairs because,

frankly, I was a little busy, but here it is in the shop. I was

able to maneuver it around the shop by using pipes under the 4x4s

under the base.

After

fixing some dings and repainting the base, I moved it to the place I'd

previously prepared, complete with a new dedicated 220 V circuit. I

had a heckofatime with incompatibility between the new paint and

the filler that Jet used on the castings on this machine.

Anywhere the filler was exposed, the urethane paint would not

dry. Even a conventional primer didn't help. I finally made

it work by spot priming with Kilz, a product mainly used to keep

staining from showing through new paint.

Reassembly was pretty much a reverse of the disassembly process:

The saddle has the feed nuts in it, and all of the one-shot lube lines to reconnect.

The table is another pretty substantial hunk of steel, and weighs well over 300 pounds. It has to slide on from one end.

I mounted the spindle assembly by balancing it on the table and using the table and knee feeds to position it.

This

manchine was new enough, and in such good shape, that I for the most

part didn't really have to do anything to it or disassemble it any

further than necessary to move it. The exception was where grease

had gotten where it shouldn't be. This necessitated disassembling

the parts of the head that included the Vari-Speed and back gear

assemblies.. Here is the back gear cleaned up and repacked with

fresh grease.

The rest of the head went on in order.

Another couple of days, and I got it wired, and the DRO, scales, lube system, X power feed, and the vise mounted. Evereything seems to be workng fine. Next step will be to dial everything in and start making some chips.

Send comments to: elhollin1@yahoo.com